15 Chapter 15. Microbial Uses in Food Biotechnology

Mahsa Alian and Venkatesh Balan

Chapter Outlin

15.6 Mushroom cultivation technology

15.7 Mushroom cultivation methods

15.8 Substrate inoculation and incubation

15.9 Fruiting body induction, harvesting, and packaging

15.10 Cleaning the growth chamber

15.11 Post-harvest processing and quality evaluation

15.12 Prospects and innovations in fungal biotechnology

Learning Objectives

By the end of this chapter, you will be able to:

- Explain the ecological, nutritional, and industrial significance of fungi and mushroom-forming species.

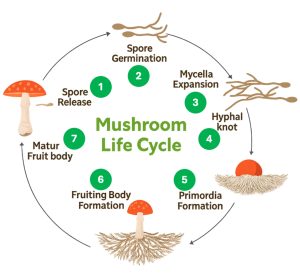

- Describe mushroom structure and life cycle, including mycelial development and fruiting body formation from spore germination through maturation.

- Differentiate major fungal groups (Basidiomycota, Ascomycota, and others) and identify key edible and medicinal species with their distinctive characteristics.

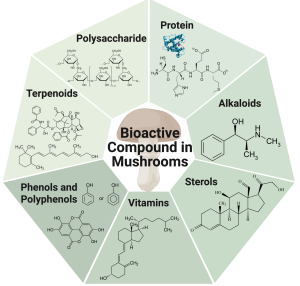

- Know the nutritional composition and bioactive compounds of mushrooms and their applications in food, medicine, and sustainable materials development.

15.1 Introduction

Fungi are a diverse and ecologically significant group of eukaryotic organisms that can be found all around the world. As decomposers, symbionts, and sometimes pathogens, fungi play essential roles in the ecosystem, biogeochemical, and environmental balance. Among these, mushroom-forming fungi stand out for their ecological contributions and their diverse applications in different industries such as biotechnology, agriculture, medicine, food, and sustainable materials development. Mushrooms—the fruiting bodies of certain fungi—typically emerge from substrates rich in lignocellulosic biomass such as wood waste, agricultural residues, and forest litter. These organic waste materials, often unsuitable and useless for human consumption, are transformed by fungi into nutrient-dense biomass, emphasizing the role of fungi as efficient recyclers and bioconverters in natural and artificial ecosystems. Instead, they are more closely related to yeasts and molds, as they all belong to the fungal kingdom. More than 14,000 species of mushrooms have been described to date, indicating significant diversity in morphology, pigmentation, growth form, and ecological preferences [1]. They have a vast, complex network of filamentous cells called hyphae below their visible fruiting bodies. These hyphae merge to form the mycelium, the main vegetative structure of the fungal organism. Mycelium thrives within the substrate, digesting organic matter by secreting extracellular enzymes and absorbing nutrients to sustain fungal growth and development. Mycelium, mainly composed of chitin—a robust structural polysaccharide—along with proteins, lipids, and bioactive glucans, shows resilience and adaptability, allowing fungi to survive under many environmental conditions [2].

Mycelium is unable to absorb nutrients due to its biological structure. It is lightweight, highly porous, and capable of expanding across large areas underground or within substrates. Under favorable environmental conditions—such as suitable temperature, humidity, carbon dioxide levels, and light—mycelium initiates the formation of fruiting bodies, completing the fungal reproductive cycle. Mushrooms eventually release spores, which can be transported by the wind or animals, and can expand and colonize new regions. Notably, mycelia networks can survive for decades or even centuries under favorable conditions, promoting the year-round growth of mushrooms [3].

Although mushrooms have been historically utilized for their medicinal and cultural properties by ancient civilizations such as the Chinese, Egyptians, Greeks, and indigenous peoples for centuries, it has only been in the last few decades that modern science has begun to explore their therapeutic potential. Numerous mushroom species contain compounds that exhibit potent immunomodulatory, antioxidant, anti-inflammatory, and anticancer properties. The current study is still validating traditional knowledge and expanding the variety of medicinal applications for mushrooms, their extracts, and derivatives. Today, only a small fraction of known mushroom species, roughly 100, are actively studied for their bioactive properties, and approximately 20 to 30 species are cultivated commercially on a global scale [4].

Global interest in sustainable food systems, alternative protein sources, and eco-friendly materials has increased, which has highlighted the potential of mushrooms and, particularly, fungal mycelium. Compared to fruiting bodies, mycelium can be produced more rapidly, with lower input requirements and greater structural flexibility. Consequently, it is becoming a versatile fundamental component with applications that extend beyond the culinary field. Mycelium-based products are being developed as sustainable substitutes for leather, plastic, Styrofoam, and even building materials [4]. In the food and healthcare industries, filamentous fungal biomass is being investigated as a meat alternative due to its high protein content and for its therapeutic potential to combat bacterial and viral infections and enhance immune responses [5].

Mushroom farming can be scaled from small and hands-on operations to large, advanced industrial setups with automated systems. Advances in cultivation technology can help farmers to grow mushrooms year-round, even in urban and indoor settings [6]. Mushroom cultivation is a multiple-step process that begins with the sterilization of lignocellulosic substrates such as straw, sawdust, etc. A sterilized substrate is inoculated with 5-10% fungal spawn and then incubated under specific environmental conditions to promote mycelial colonization and the development of fruiting bodies. Fresh mushrooms are used for culinary purposes but can also be processed into different value-added products such as powders, capsules, and ethanol-based tinctures.

This chapter provides a comprehensive overview of fungal biology and biotechnology, focusing on the physiology, life cycle, and structure of fungi. Readers will learn the characteristics that differentiate fungi from other organisms, such as their nutrition, cell structure, reproductive mechanisms, and ecological interactions. Additionally, the chapter will explore the practical aspects of the mushroom life cycle and techniques such as spore germination and mycelial expansion, substrate preparation, and harvesting strategies. It will distinguish between laboratory-scale research cultivation and large-scale industrial production, addressing the specific technological requirements and challenges of each. The ecological and economic aspects of fungal biotechnology will also be explored, emphasizing its role in promoting circular economies, minimizing waste, and advancing sustainable development.

15.2 Fungi

Fungi are classified into specific taxonomic groups based on their reproductive structures, physical characteristics, and molecular phylogenetic affiliations. Basidiomycota and Ascomycota are the two most significant phyla among various fungal phyla, which include nearly all edible, medicinal, and commercially cultivated mushrooms (Table 15.1).

Table 15.1 Key Genera of Fungi by Phylum and Biotechnological Importance.

| Fungal Phylum | Key Examples | Characteristics & Biotechnological Importance |

|---|---|---|

| Basidiomycetes | Agaricus bisporus, Ganoderma spp., Pleurotus sp. | Includes most edible and medicinal mushrooms. Reproduce via basidia producing basidiospores. Important for food, traditional medicine, and bioremediation. |

| Ascomycetes | Morchella (morels), Cordyceps | Includes a wide range of fungi, some edible and some with medicinal properties. Reproduction occurs through asci containing ascospores. Also important in fermentation and drug discovery. |

| Zygomycetes and Glomeromycetes | (No specific genera mentioned in context, but examples include Rhizopus for Zygomycetes) | Less commonly used in mushroom production but important in industrial fermentation (e.g., organic acid production) and mycorrhizal symbiosis (Glomeromycetes forming associations with plant roots, enhancing nutrient uptake). |

| Deuteromycetes (Fungi Imperfecti) | Penicillium species | Fungi with no known sexual stage (or if present, not observed). Often important in biotechnology, particularly to produce antibiotics (e.g., penicillin) and various industrial enzymes. |

Other groups, such as Zygomycota, Glomeromycota, and Deuteromycetes, do not typically exhibit fruiting body formation, but they play important roles in industrial applications and the ecosystem [1].

Basidiomycota (Basidiomycetes)

Basidiomycota are the largest and most recognizable category of mushroom-producing fungi. These fungi reproduce sexually by club-shaped cells known as basidia, which are generally located on the gills, holes, or spines of the fruiting body. Each basidium generates basidiospores that are disseminated into the environment for reproduction. The visible mushroom is a reproductive structure supported by an extensive underground mycelial network, which is responsible for nutrient uptake and substrate decomposition [7]. Basidiomycetes include a wide variety of edible, medicinal, and toxic mushrooms. Agaricus bisporus (button mushroom), Ganoderma lucidum (reishi), Pleurotus ostreatus (oyster mushroom), and Coprinus comatus (shaggy mane) are the most famous ones. Subdivisions within this phylum include:

- Hymenomycetes, which produce spores on the exposed surfaces (e.g., gilled mushrooms like Agaricus), and

- Gasteromycetes, which produce spores internally (e.g., puffballs like Lycoperdon).

Ascomycota (Ascomycetes)

Ascomycetes are the second-largest group of fungi. Some species can form fruiting bodies that resemble mushrooms. They reproduce via ascospores, which are formed in sac-like structures, the asci, typically contained in a fruiting body, the ascocarp. Although ascomycetes are more common in molds and yeasts, some species, such as Morchella (morels) and Tuber (truffles), are notable for their culinary and economic value. In contrast to the Basidiomycetes, many Ascomycetes do not form conspicuous fruiting bodies, and those that do often have a unique morphology. Morchella forms hollow, spongy caps above ground, while Tuber produces underground fruiting bodies that form symbiotic associations with plant roots [8].

Other Fungal Groups

- Zygomycota and Glomeromycota: These phyla include fungi with simpler reproductive structures and are not commonly associated with mushroom formation. However, they are essential in soil health, plant symbiosis (e.g., arbuscular mycorrhizal fungi), and industrial fermentation processes.

- Deuteromycetes (Fungi Imperfecti): These include fungi that reproduce asexually and lack a known sexual reproductive stage. Many species, such as Penicillium and Aspergillus, are pivotal in biotechnology, antibiotics production, and enzyme manufacturing [9].

15.3 Mushroom life cycle

Fungi play an essential role in organic matter decomposition by secreting extracellular enzymes that break down complex bio-molecules into simpler, absorb-able nutrients. To access carbon and nitrogen sources from their environment, fungi produce cellulases and hemicellulases that degrade plant cell wall components—cellulose and hemicellulose—into simple sugars like glucose and xylose. Additionally, proteases are secreted to break down proteins into amino acids. These breakdown products are then absorbed by the fungal hyphae and used as carbon and nitrogen sources for fuel energy production, facilitating biomass formation and mycelial growth. This enzyme secretion capability allows fungi to thrive on a wide range of lignocellulosic and protein-rich substrates in forest and agricultural fields. Mushrooms are the reproductive structures of certain fungi, emerging through a complex and biological process that begins with invisible spores and arises in the fruiting bodies. This life cycle represents a remarkable transition from microscopic cellular growth to macroscopic structures capable of reproduction and environmental interaction. Each phase requires specific genetic, physiological, and environmental cues to facilitate development [10]. The process is outlined below and illustrated in Figure 15.1.

Figure 15.1 Different Life cycle stages of a mushroom from fungal spores. Alian. M, Balan. V. (CC0 1.0).

The life cycle begins when microscopic reproductive units, called spores, are released from mature fungi into a suitable substrate. Spore germination can occur naturally and artificially, e.g., when the spores land on rotting logs or forest litter, or by inoculation in controlled cultivation systems. The enriched substrate with high levels of nutrients, such as hardwood logs, straw, sawdust, or various types of grain. The spores remain inactive until the environmental conditions, including temperature, humidity, oxygen content, and pH value, are favorable for growth after they have been deposited.

Stage 1 – Mushroom spore release: Reproductive spores are ejected from specialized structures by hydraulic mechanisms involving rapid moisture accumulation, reaching velocities of up to 1.8 m/s over millimeter distances within microseconds.

Stage 2 – Spore germination: Under optimal environmental parameters (temperature, humidity, nutrients), the spores are hydrated, and their cells expand, initiating the formation of germ tubes and the subsequent development of hyphae.

Stage 3 – Mycelial Expansion: The mycelial network multiplies by colonizing substrates through the secretion of extracellular enzymes (cellulases, ligninases, proteases) to degrade organic matter. The simultaneous production of antimicrobial secondary metabolites facilitates the competitive advantage and the acquisition of resources.

Stage 4 – Hyphal Knot Formation: After complete colonization of the substrate and specific environmental triggers (CO₂ content, photo stimulation, nutrient deficiency), hyphae aggregate into compact nodular structures, indicating the transition to reproduction.

Stage 5 – Primordia Formation: Hyphal aggregates differentiate into embryonic fruiting bodies (“pins”) through intensive metabolic processes involving cellular specialization and polysaccharide biosynthesis for the formation of structural tissue.

Stage 6 – Fruit Body Selection: Resource allocation focuses on optimal primordia based on environmental factors (airflow, lighting, humidity, spatial constraints), which ensure maximum reproductive performance through selective development.

Stage 7 – Mature Fruit Body Development: Fully developed sporocarps facilitate massive spore release through environmental dissemination mechanisms while maintaining viable mycelial networks for subsequent reproductive cycles.

15.4 Type of Mushroom

Mushrooms can be classified into two categories: edible and toxic mushrooms. Edible mushrooms have been popular for their nutritional richness, medicinal potential, and culinary versatility, and are safe for consumption, while poisonous mushrooms can be a significant health threat. Even small quantities of mushroom species can lead to severe liver or kidney damage, neurological effects, or fatality. Some fungi, such as Ophiocordyceps sinensis (commonly known as Yartsa Gunbu), belong to psychoactive or “magic” mushrooms and have been used in medicine and spiritual occasions due to the high quantity of hallucinogenic compounds Psilocybin, Psilocin, Baeocystin, and Norbaeocystin. Proper identification is crucial for distinguishing between edible and toxic strains. Although most edible mushrooms are generally safe, some can cause allergic reactions, and touching toxic species may be risky due to their toxins, which can be absorbed through the skin [11].

Edible Mushroom

A mushroom is classified as edible when it contains no harmful toxins and has pleasant sensory and nutritional characteristics. Edible mushrooms are macro fungi with fruiting bodies that grow either above ground (epigeous) or below ground (hypogeous) and are safe for human consumption.

Figure 15.2 Most popular edible mushrooms. Alian. M, Balan. V. (CC0 1.0).

They are harvested manually and have been used as ingredients in diverse cuisines due to their flavors, textures, and health properties. Figure 15.2 illustrates 16 globally popular and domestically produced edible mushroom species [12].

Button Mushroom (Agaricus bisporus)

Button mushrooms are the most widely cultivated edible mushrooms worldwide and have been popular due to their nutritional, culinary, and medicinal benefits. They are classified into two main types—white and brown (also known as crimini), and are rich in protein, amino acids, healthy fats, fiber, vitamins, phenolic compounds, and terpenoid content. Button mushrooms can be cultivated on nutrient-rich compost that is made from substrates such as straw, hay, and poultry manure. Successful mushroom cultivation requires accurate control of temperature, humidity, airflow, light, and CO2 levels. Compost is initially pasteurized at 80–90°F for several days to eliminate pathogens, and then cooler temperatures (60–70°F) are required to produce a fruiting body. High humidity (above 80%), proper air circulation, and ventilation ensure optimal growth, achieving biological efficiencies of up to 20%. Advanced technologies can boost yield, efficiency, and nutritional quality [13].

Oyster Mushroom (Pleurotus spp.)

Oyster mushrooms are the second most cultivated mushroom group globally, accounting for over 16% of global production. They are known for their wide color range, such as white, grey, pink, yellow, salmon, and blue, and include several species such as Pleurotus ostreatus (common oyster), Pleurotus sajor-caju (Indian oyster), Pleurotus pulmonarius (Phoenix oyster or lung oyster), Pleurotus djamor (Pink oyster), Pleurotus columbinus (Blue oyster), Pleurotus eryngii (King oyster), Pleurotus citrinopileatus (Golden oyster), Pleurotus salmoneostramineus (Salmon pink oyster). Oysters have become popular and valued due to their short cultivation cycle, low input requirements, high yield, and ability to grow on lignocellulosic agricultural waste, such as straw, sawdust, and sugarcane bagasse, without a composting cycle. Optimal conditions include temperatures of 20–35°C for spawning and 10–15°C for fruiting, with humidity levels of 66–70%. Their rapid growth and high biological efficiency (often exceeding 100%) make them ideal for both small-scale and commercial farms.

Shiitake Mushroom (Lentinula edodes)

Shiitake mushrooms are widely consumed for their umami flavor and medicinal compounds. They were initially cultivated in East Asia and are now cultivated worldwide. They are known for antimicrobial, antitumor, antioxidant, antiviral, and immunomodulatory effects, due to their bioactive compounds like lentinan and eritadenine. Shiitake can be grown on sawdust blocks or hardwood logs. Ideal growth conditions are cool temperatures around 55–70 °F with 80–90% humidity. With proper strain selection and environmental control, biological efficiency (ratio of the fresh weight of mushrooms harvested to the dry weight of the substrate used) can reach up to 100%, and innovations in substrate formulation can lead to enhancing its commercial scalability [14].

Other varieties

Beyond commonly cultivated mushrooms like button, oyster, and shiitake, a diverse range of gourmet and specialty mushrooms are grown worldwide. Enoki (Flammulina velutipes) features long, slender stems with tiny caps that are widely used in East Asian cuisine. Nameko (Pholiota nameko) has a gelatinous cap and a mild flavor. Porcini (Boletus edulis), famous in European dishes, offers a rich, meaty texture. Morels (Morchella spp.) are seasonal delicacies popular for their earthy flavor. Truffles (Tuber spp.) are subterranean fungi that form symbiotic relationships with tree roots and are known for their odor. The black trumpet (Craterellus cornucopioides) is another wild gourmet mushroom known for its delicate flavor. The white gall fungus (Tremella fuciformis) is used in traditional Chinese medicine and desserts. The rice straw mushroom (Volvariella volvacea) grows in tropical climates and is cultivated on rice straw. The wood ear (Auricularia auricula-judae) has a chewy texture and is often added to soups and salads. Maitake (Grifola frondosa), also known as the “hen of the woods,” contains immune-boosting beta-glucans and is used in nutritional products. The milky white mushroom (Calocybe indica) is valuable due to its heat tolerance and is cultivated in tropical regions. Chanterelles (Cantharellus spp.) are aromatic, trumpet-shaped mushrooms that are used in gourmet cuisine. Shaggy mane (Coprinus comatus), or ink cap mushroom, is best eaten fresh because of its delicate texture. [15].

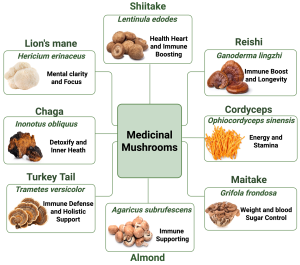

Medicinal Mushrooms

Fungi provide a diverse range of bioactive compounds that have essential therapeutic advantages and potential in both traditional medicine and contemporary biomedical research. The components include polysaccharides, triterpenoids, terpenes, phenolic acids, lectins, peptides, and other secondary metabolites. Many of these molecules exhibit anti-inflammatory, antioxidant, antimicrobial, immunomodulatory, neuroprotective, and anticancer activities.

Figure 15.3 The most important medicinal mushrooms and their health benefits. Alian. M, Balan. V. (CC0 1.0).

Fungi have long been a source of life-saving medicines, with the most famous example being penicillin, derived from Penicillium species, which has been used as a treatment for bacterial infections. To date, only around 10% of fungal biodiversity has been explored, and the full potential of fungal metabolites and secretions remains unknown and requires further research. Medicinal mushrooms are now widely researched for use in nutraceuticals, functional foods, and integrative medicine, particularly in East Asia, where they have been an integral part of traditional healthcare for centuries [16]. Some of the most widely studied and commercially available medicinal mushrooms are shown in Figure 15.3.

Reishi (Ganoderma lucidum)

It is one of the most extensively studied medicinal mushrooms, which is also known as the “mushroom of immortality”. It is rich in triterpenoids (e.g., ganoderic acids, lucidenic acids), polysaccharides (e.g., β-glucans, ganoderans), peptides, and polyphenols. Laboratory and animal studies suggest a wide range of bioactivities, including Anticancer, Immunomodulatory, Antioxidant, Anti-inflammatory, Cardioprotective, antimicrobial, and Anti-diabetic. Some clinical trials report improvements in immune system function and quality of life in cancer patients who are receiving Reishi supplements. However, large-scale human studies are required to confirm its anticancer efficacy and optimal dosages. Beech Mushroom (Hypsizygus tessellatus): It has a nutty flavor and a firm texture, which is often cultivated in Asia. Each species has unique features in terms of taste, texture, growing requirements, and nutritional profile. Commercial mushroom production has increased due to ongoing research and advancements in controlled environment cultivation. As a result, a broader variety of mushrooms can be cultivated in different conditions to meet a variety of climate conditions and consumer preferences.

Turkey tail (Coriolus versicolor)

This mushroom is known for its immune-supportive effects, primarily attributed to two compounds: Polysaccharo-peptide (PSP) and polysaccharide-k (PSK). Both PSP and PSK have been shown to enhance immune function, inhibit tumor growth, provide antioxidant and anti-inflammatory effects, and act synergistically with chemotherapy, especially in lung, breast, and gastric cancers; PSK is approved as an adjuvant cancer therapy in Japan. While results have been promising, further controlled clinical studies are necessary to establish its efficacy across a broader range of conditions [17].

Lion’s mane (Hericium erinaceus)

This is unique among medicinal mushrooms for its neurotrophic properties. It contains Hericenones (found in the fruiting body) and Erinacines (found in the mycelium). These diterpenoid compounds stimulate the production of nerve growth factors (NGF), crucial for the survival and regeneration of neurons. Research suggests: Neuroprotection against Alzheimer’s and Parkinson’s disease, Improved memory and cognition, Mood regulation, including reduced anxiety and depression, Support for nerve repair in peripheral neuropathy, Preliminary human studies show promise, particularly in mild cognitive impairment and mental wellness, but larger randomized trials are needed [18].

Cordyceps (Cordyceps sinensis and Cordyceps militaris):

This is a parasitic fungus traditionally harvested from high-altitude regions in Tibet and China. Due to the rarity of wild C. sinensis, C. militaris is now widely cultivated and used for its comparable bioactivity. Key compounds include Cordycepin (3’-deoxyadenosine), Known for its antitumor, anti-inflammatory, and antiviral properties; Polysaccharides: Enhance immune modulation and antioxidant defense; Adenosine and related nucleotides: Support energy metabolism and cardiovascular health; Medicinal uses supported by studies include: Improved physical stamina and athletic performance, Enhanced oxygen utilization and respiratory function, Anti-fatigue and anti-aging effects, Support for libido and reproductive health, Adjunctive treatment for chronic kidney disease and metabolic disorders. Cordyceps are widely consumed as capsules, powders, or extracts and are regarded as one of the top adaptogenic fungi in traditional and modern herbal medicine [19].

Other medicinal mushrooms

Other medicinal mushrooms have gained in importance due to their therapeutic potential and benefits. Chaga (Inonotus obliquus), which grows on birch trees, is known for its high levels of antioxidant compounds such as beta-glucan and beta-glucan acid and is traditionally used to support immune health and reduce inflammation. Maitake (Grifola frondosa), often referred to as the ‘hen of the woods’,” contains D-fraction β-glucans [a type of β-(1→3), β-(1→6)-glucan], that have anti-tumor and immunomodulatory properties. Shiitake (Lentinula edodes) is not only a popular edible mushroom. Still, it is also valued for its compound lentinan, which supports immune function and has been studied as a complementary therapy for cancer. Muril (Agaricus blazei) is rich in bioactive ABL polysaccharides and has shown promise in improving immune response and controlling blood sugar levels. Individually and in combination, these mushrooms contribute to the expanding field of medicinal mushrooms and offer multiple applications in integrative health and functional nutrition.

15.5 Mushroom compositio

Nutritional value of different mushrooms

Edible mushrooms are highly valued for their culinary appeal and nutritional profile, which has made them popular in many dishes and diets. They are low in calories and fat while delivering a wide variety of essential nutrients, including high-quality proteins, carbohydrates, dietary fiber, vitamins, and minerals. Several species also contain unique bioactive compounds that boost human health.

Table 15.2 Nutritional value of some of the most popular edible mushrooms (USDA).

| Nutritional values | Button | Oyster | Shiitake | Morel | Enoki | Maitake |

|---|---|---|---|---|---|---|

| Energy (kcal/100 g) | 31 | 33 | 34 | 31 | 37 | 31 |

| Macronutrient (g/100 g) | ||||||

| Carbohydrate | 3.35 | 4.08 | 6.79 | 5.1 | 7.81 | 6.97 |

| Protein | 7.5 | 3.31 | 2.24 | 3.12 | 2.66 | 10.3 |

| Fat | 3.2 | 0.37 | 6.79 | 0.57 | 0.29 | 0.19 |

| Dietary fiber | 3.6 | 2.3 | 2.5 | 2.8 | 2.7 | 2.7 |

| Minerals (mg/100 g) | ||||||

| Calcium | 5 | 3 | 2 | 43 | 0 | 1 |

| Iron | 0.23 | 1.33 | 0.41 | 12.2 | 1.15 | 0.3 |

| Magnesium | 10.2 | 18 | 20 | 19 | 16 | 10 |

| Phosphorus | 93 | 120 | 112 | 194 | 105 | 74 |

| Potassium | 373 | 420 | 304 | 411 | 359 | 204 |

| Sodium | 6 | 18 | 9 | 21 | 3 | 1 |

| Zinc | 0.51 | 0.77 | 1.03 | 2.03 | 0.65 | 0.75 |

Mushrooms contain approximately 3–8% carbohydrates (dry weight), including monosaccharides like glucose, disaccharides like trehalose, and complex polysaccharides such as chitin, mannans, and β-glucans (Table 15.2). effects. Most of the carbohydrate content in mushrooms is non-digestible, contributing to their dietary fiber content. Mushrooms are also an excellent source of high-quality plant-based protein, comprising approximately 19–35% of their dry weight. They offer essential amino acids, with high levels of lysine, leucine, and valine, which are often limited in cereals, making mushrooms a great source of protein, particularly for vegetarians and vegans [20].

These β-glucans are especially important for their immunomodulatory and cholesterol-lowering capacity. Mushrooms provide valuable dietary fiber, containing both soluble forms, such as β-glucans, and insoluble types, such as chitin. With fiber making up 7-10% of their dry weight, mushrooms support digestive wellness, help regulate blood sugar levels, promote colon health, and contribute to feelings of fullness. Also, mushrooms are naturally low in fat, typically containing 2–8% fat (dry weight). The lipid profile is mainly unsaturated fatty acids, especially linoleic acid (omega-6) and oleic acid (omega-9), with negligible amounts of saturated fats. This composition supports cardiovascular health and makes mushrooms a heart-friendly food choice [21].

Major Bioactive Compounds in Mushrooms

Medicinal mushrooms are rich in a diverse array of bioactive compounds, which contribute to their therapeutic potential in traditional and modern medicine. These compounds—ranging from complex polysaccharides to phenolic compounds and sterols—play critical roles in modulating immune responses, combating oxidative stress, inhibiting tumor growth, and preventing microbial infections (Figure 15.4).

Figure 15.4 Bioactive compounds in mushrooms. Some of the major classes of compounds include polysaccharides, terpenoids, alkaloids, Proteins/peptides, Sterols, terpenoids, and polyphenols. Alian. M, Balan. V. (CC0 1.0).

The synergistic effects of these natural compounds offer a promising foundation for the development of nutraceuticals and pharmaceutical agents.

Polysaccharides (e.g., β-glucans)

Polysaccharides are among the most studied bioactives in mushrooms, with β-glucans being particularly prominent. These complex carbohydrates are known for their immunomodulatory properties—activating macrophages, dendritic cells, and natural killer cells. Beyond immune stimulation, β-glucans demonstrate anticancer, anti-inflammatory, and antioxidant effects. Different edible mushrooms contain various types of a β-(1→3)-glucan with β-(1→6) branches, which vary in structure and biological activity. Some examples include Shiitake (Lentinan), Oyster (Pleuran), Split Gill (Schizophyllan), Maitake (Grifolan), Turkey Tail ( Polysaccharide K), and Reishi (Ganoderan A, B, C), and are increasingly used in immune-boosting supplements.

Triterpenoids and Sterols (e.g., Ganoderic acids, Ergosterol)

Triterpenoids, particularly ganoderic and lucidenic acids found in Ganoderma species, possess a broad spectrum of biological activities, including anti-inflammatory, hepatoprotective, antioxidant, antitumor, and cardioprotective effects. These compounds can modulate inflammatory pathways and inhibit tumor cell proliferation. Ergosterol, another key sterol found in fungal membranes, has shown anticancer potential and, when exposed to ultraviolet light, is converted to vitamin D2, making mushrooms one of the rare non-animal sources of this essential vitamin.

Phenolic Compounds and Flavonoids

Phenolics and flavonoids are natural antioxidants that scavenge free radicals and reduce oxidative damage in cells. These compounds contribute to the anti-aging, anti-inflammatory, and neuroprotective properties of mushrooms. Some mushrooms such as Maitake (Grifola frondosa), Shiitake, and Pleurotus species are rich in phenolic acids such as gallic acid, chlorogenic acid, and flavonoids like quercetin and kaempferol.

Peptides and Lectins

Bioactive peptides in mushrooms function as antimicrobial, antiviral, and anticancer agents, often by disrupting microbial membranes or modulating immune signaling pathways. Lectins, another class of proteins, are carbohydrate-binding molecules that exhibit selective cytotoxicity against cancer cells and regulate immune reactions. They are found in some fungi, such as the button (Agaricus bisporus) and the golden needle (Flammulina velutipes), and are being investigated for their pharmaceutical benefits.

Ergosterol and Vitamin D2

As a fungal sterol, ergosterol plays a structural role in fungal cell membranes. It also serves as a precursor to vitamin D2 (ergocalciferol), which is produced when mushrooms are exposed to UV light. Vitamin D2 supports bone health, immune regulation, and may reduce the risk of chronic diseases such as osteoporosis and cardiovascular disorders.

Polyketides

Polyketides are secondary metabolites produced by some medicinal mushrooms, especially Ganoderma species. These compounds exhibit antitumor, antifungal, and antiviral effects and are structurally diverse, making them attractive for pharmaceutical drug development. Their mechanisms of action include inhibition of DNA synthesis, disruption of microbial cell walls, and modulation of inflammatory pathways. Several groundbreaking drugs have been discovered or derived from mushrooms and other fungi, demonstrating their immense value in pharmaceutical science. Among the most significant are Penicillin from Penicillium notatum, the first proper antibiotic that revolutionized bacterial infection treatment. Cyclosporine, isolated from Tolypocladium inflatum, enabled routine organ transplantation by suppressing immune rejection. Lovastatin, derived from Aspergillus terreus and some Pleurotus species, pioneered cholesterol-lowering statins to combat cardiovascular disease. The antifungal griseofulvin, from Penicillium griseofulvum, treats skin infections like ringworm, while echinocandins (e.g., caspofungin) from Glarea lozoyensis are crucial for treating invasive fungal infections. The hallucinogenic compound psilocybin from Psilocybe mushrooms is now under clinical investigation for its potential to treat depression, anxiety, and PTSD. Additionally, ergot alkaloids from Claviceps purpurea have applications in migraine relief and labor induction. Collectively, these fungal-derived drugs have transformed medicine across multiple therapeutic areas [22].

15.6 Mushroom Cultivation Technology

Mushroom production technology comprises a variety of controlled processes that optimize the growth and yield of edible and medicinal mushrooms. It starts with the production of pure cultures and mushroom spawn (usually on grain or sawdust), followed by the preparation of the substrate from lignocellulosic materials such as straw, sawdust, or compost. The substrates are sterilized or pasteurized, then inoculated with the spawn and incubated under optimal conditions, such as suitable temperature and humidity, for colonization with mycelia. After colonization, the environmental conditions, such as light, fresh air exchange, and humidity, are adjusted to initiate fruiting. Fungal productivity has been significantly increased thanks to automated climate control, substrate formulations, and effective contamination management. This made the process more efficient, scalable, and accessible to both small growers and larger farms.

Core Facilities and Equipment

Mycology laboratories are equipped with essential equipment such as laminar flow bonnets, autoclaves, incubators, and growth chambers to enable sterile handling and controlled cultivation of fungi (Figure 5). These facilities support every stage of fungal research, from culture isolation to fungal fruiting. Technical details of these devices and how they work can be found below.

Laminar flow hood

Vertical and horizontal laminar flow hoods are indispensable in biological laboratories and keep the work area free of any contamination. They provide an even, filtered airflow that creates a clean environment for experiments. This unidirectional airflow ensures that the surfaces and materials within the hood remain aseptic, which is crucial for reliable and accurate results in scientific research. These hoods employ high-efficiency particulate air (HEPA) filters that remove at least 99.97% of airborne particles ≥ 0.3 μm in size, creating a sterile, particle-free environment that is ideal for microbiological, pharmaceutical, and tissue culture procedures (Figure 15.5).

Figure 15.5 Different tools and machines are needed for mycology. Some of the essential machines include a laminar flow hood, autoclaves, incubators, growth chambers, and other additional machinery. Alian. M, Balan. V. (CC0 1.0).

In a vertical laminar flow hood, the filtered air is forced downwards in uniform, parallel streamlines by a ceiling-mounted HEPA filter. This top-to-bottom laminar airflow minimizes contamination from both the operator and the environment. The air flows over the work surface and exits the bonnet through a front grille, trapping all particles in the hood and preventing them from escaping into the surrounding laboratory area. In contrast, a horizontal laminar flow hood has air that passes through a rear-mounted HEPA filter and is directed horizontally towards the user. This configuration provides excellent protection for the use of a vacuum cleaner to remove experimental materials by constantly extracting clean air from the work area. Still, it offers less protection for the operator from possible exposure. In both designs, the use of laminar (non-turbulent) airflow is essential to avoid unpredictable airflows and maintain sterility throughout the work area. To ensure maximum sterility and minimize contamination during use, the following practices are recommended:

- Pre-sterilize the work area: Wipe all internal surfaces with 70% ethanol or a suitable disinfectant, followed by at least 15 minutes of germicidal UV-C irradiation with the sash or viewing window fully closed.

- Organize the workflow carefully: arrange the materials in a logical order that prevents cross-contamination. Keep sterile items behind potential contaminants to avoid exposure from air moving over them.

- Avoid clutter: Avoid cluttering the cabinet with equipment or consumables, as this interrupts laminar airflow and increases the risk of contamination.

- Sterilize items before insertion: Ensure that hands, gloves, and any tools or containers inserted into the cabinet are sterilized or thoroughly wiped with ethanol.

- Maintain a safe working area: Place all materials and operations at least 15 cm from the front edge of the cabinet. This buffer zone helps to avoid contamination from peripheral air currents that could mix with the room air.

- Regular maintenance and performance checks: Schedule routine checks of HEPA filter integrity, airflow velocity, and cabinet pressure. Timely filter replacement and leak checks are essential to maintain the cabinet’s optimal function and 99.97% particle removal efficiency.

Following protocols and understanding the airflow dynamics of vertical and horizontal laminar flow hoods significantly reduces the risk of contamination in laboratories, which is essential for sensitive biological and pharmaceutical operations.

Autoclave

Autoclaves are sterilization devices used in laboratories, medical facilities, and mushroom cultivation to eliminate microbial organisms such as bacteria, viruses, fungi, and spores through the application of saturated high-pressure steam. The principle of autoclaving is moist heat sterilization, which is much more effective than dry heat due to better heat transfer and the ability to denature proteins and destroy cell membranes quickly. The typical operating parameters for an autoclave are 121°C (250°F) at 15 psi (pounds per square inch) for 15–30 minutes, depending on the volume and type of material to be sterilized. Some modern autoclaves can operate at higher temperatures (e.g., 134°C) for shorter periods. The process begins with the removal of air from the chamber (by gravity displacement or pre-vacuum), followed by steam injection, pressurization, and heating. Once the desired temperature and pressure have been reached, the materials are kept under these conditions for a specific period to ensure complete sterilization. After the sterilization phase, the steam is released, the pressure is gradually reduced, and the chamber is cooled down before the items are removed. Autoclaves are generally used to sterilize growth media, substrates, glassware, instruments, and waste [23].

Incubator

Incubators are essential pieces of equipment in fungal biotechnology laboratories, providing a controlled environment to ensure optimal growth and development of the mycelium. These devices ensure precise maintenance of temperature, humidity, and sometimes CO₂ levels, which are essential for consistent results in fungal culture. Most fungal species thrive at temperatures between 20°C and 30°C, and incubators provide stable conditions during the colonization of culture media, grain spawn, or liquid cultures. Modern incubators can include programmable settings, humidity control, and air circulation to ensure uniform conditions throughout the chamber.

Growth chambers:

Fungal growth chambers provide a suitable environment for the growth of fungi. They can maintain temperatures between 15 and 35°C, depending on the type of mushrooms being cultivated, and support different stages of growth. Growth chambers can tolerate high humidity, usually between 80 and 95%, which is essential for mushroom cultivation and prevents the mushrooms from drying out, and promotes the formation of primordia. They are equipped with fluorescent or LED sources (100–1000 lux) to provide specific wavelengths and photoperiods that stimulate the development of the fruiting bodies. The CO₂ content (0–2000 ppm) is adjusted via ventilation systems. Lower CO₂ concentrations are recommended for fruiting, while higher concentrations stimulate mycelium growth – together, these environmental controls enable consistent, high-quality mushroom production throughout the year. Automated Internet-of-Things systems and sensors integrated into the growth chambers allow real-time monitoring and precise adjustments and can increase yield and reduce labor.

Smart IoT technologies:

Humidifiers, CO₂ scrubbers, and lighting systems are essential for mushroom cultivation to provide optimal conditions for growth and development. Humidifiers ensure a high relative humidity (80–95%), which is one of the critical parameters for the germination and maturation of fruiting bodies. A low CO₂ content is required to promote cap expansion and initiate fruiting bodies. Lighting systems, often LED or fluorescent tubes, provide specific light intensities and photoperiods (e.g., 12 hours per day) to stimulate development in light-responsive structures in fungi [6].

15.7 Mushroom cultivation method

Fungal tissue culture is the aseptic in vitro propagation of fungal cells or tissues under precisely manipulated nutritional, hormonal, and environmental conditions to produce high-quality metabolites or clones. Sterile cultivation enables the production of customized media with additional bioactive molecules, growth regulators, different carbon sources, or precursors that feed specific biochemical metabolic pathways. This allows the production of therapeutic proteins, enzymes, or secondary metabolites on a commercial scale, which is not possible with conventional mushroom cultivation.

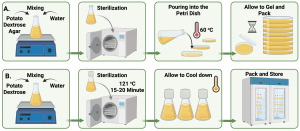

Media preparation for mycelium growth

Media preparation is an essential step in fungal biotechnology and provides the necessary nutrients for optimal mycelial growth under sterile conditions. Two main types of culture media are used: solid (agar-based) and liquid. Potato dextrose agar (PDA), malt extract agar (MEA), and Sabouraud dextrose agar (SDA) are used for solid-based media by dissolving the ingredients in distilled water, adjusting the pH (typically around 5-6), and sterilizing the mixture for 15 minutes at 121°C in an autoclave. Once the sterile medium has cooled to 50–60°C, it is aseptically poured into petri dishes (20–25 ml per plate), solidified, sealed, and stored upside down at 4°C. Liquid media such as potato dextrose broth (PDB) are prepared similarly, but without agar (Figure 15.6).

Figure 15.6 Culture media preparation methods. Here, (A) Solid agar medium for surface mycelial growth; (B) Liquid medium for submerged mycelial cultivation. Alian. M, Balan. V. (CC0 1.0).

Once the broth has been sterilized and cooled, it is bottled in a sterile environment and then inoculated with fungal cultures. To provide better aeration and uniform growth of the mycelium, the flasks are often placed on rotating shakers for incubation.

Cultivation of fungi

Fungal tissue culture is a fundamental technique in mycology that is used to isolate, preserve, and propagate pure fungal strains under sterile conditions. A small piece of tissue — usually from a fruiting body or an actively growing mycelium – is transferred to a nutrient-rich medium. Two main types of media are used: solid (e.g., Potato Dextrose Agar, PDA) and liquid (e.g., Potato Dextrose Broth, PDB). In solid media, the tissue is placed on sterilized agar plates that support radial mycelial growth and allow visual monitoring of morphology and contamination (Figure 15.7). This method is ideal for the establishment of cultures from spores or tissue and for the long-term maintenance of strains. In liquid media, the mycelial plugs or spores are transferred to flasks containing sterilized broth. Since there is no agar, the fungus grows in suspension in the medium and forms clumps or pellets. To prevent the formation of surface mats and to ensure aeration, the cultures are either placed on rotary shakers or mixed at regular intervals. Liquid media are well-suited for the rapid production of biomass, the extraction of secondary metabolites, and the preparation of inoculum for spawning or fermentation processes.

Figure 15.7 Tissue culturing of fungus on growth media like PDA in a sterile Petri dish. Alian. M, Balan. V. (CC0 1.0).

Petri dishes should be sealed with parafilm, and liquid culture bottles should be sealed with cotton plugs or breathable caps. After inoculation, the cultures are incubated at species-specific temperatures. As soon as the first mycelial growth begins, the Petri dishes should be inverted to prevent condensation from dripping onto the surface plates. Fungal growth should be checked every two days, and contaminated cultures should be discarded. Fully colonized plates should be stored at 4°C to prevent further development. To maintain a fresh culture, it is recommended to subculture fresh agar every two months [24, 25].

Spawn preparation steps

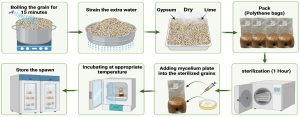

Seed spawn is a key element in mushroom cultivation. It consists of sterilized grains that are colonized by mycelium and used to inoculate bulk substrates. The process begins with the thorough hydration of grains such as wheat, rye, or sorghum. Once the grains are thoroughly soaked and drained, they are enriched with minerals to promote mycelial growth — typically 10-12 g of gypsum (CaSO₄-2H₂O) and 3-5 g of lime (CaCO₃) per kilogram of moist grains. These additives improve the texture, prevent clumping, and buffer the pH value. The supplemented grains are then sterilized in an autoclave at 121°C for 30–60 minutes to remove impurities. After complete cooling under sterile conditions, the grains are ready for inoculation. Inoculation can be carried out with either solid or liquid fungal cultures. In solid inoculation, small wedges of agar colonized with mycelium (from a petri dish) are transferred into the sterilized grains using sterile tools (Figure 15.8).

Figure 15.8 Grain spawn preparation steps. This process involves cleaning and straining water from grains, followed by a brief boil for a few minutes. Lime and gypsum are then added, and the mixture is packed in polybags. After the bags undergo sterilization, they are inoculated with liquid mycelium or fungal spores grown on a culture plate and incubated at the right temperature and humidity conditions to produce solid spawn. Alian. M, Balan. V. (CC0 1.0).

These solid chunks serve as inoculation points for mycelial propagation. In liquid inoculation, a mycelium-rich suspension is injected directly into the grains using a sterile syringe. This method enables even distribution and generally leads to faster colonization. Both types of inocula are obtained from tissue cultures of the desired fungal strain. After inoculation, the grains are incubated in jars or bags at species-specific temperatures so that the mycelium can fully colonize the grains. The resulting grain spawn is then used to inoculate larger fruit substrates for mushroom production. A similar method is used to produce sawdust spawn by simply changing the substrate [26, 27].

Substrate for mushroom production

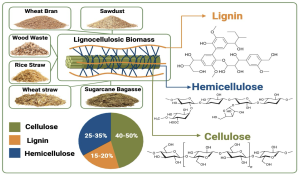

Mushroom substrates, such as cereals and lignocellulosic biomass, serve both as physical support and as a food source for the cultivation of mushrooms. Cereals such as wheat, sorghum, or millet are rich in starch, which consists mainly of α-1,4 glycosidic bonds, and contain small amounts of hemicellulose, protein, and traces of lignin (Figure 15.9). In contrast, lignocellulosic biomass— obtained from agricultural and forestry residues— consists mainly of cellulose (β-1,4 bonds), hemicellulose (a heteropolymer of various sugars), and lignin (a complex aromatic polymer).

Figure 15.9 Different lignocellulosic biomasses used as substrates for producing mushrooms, along with their three major compositions —cellulose, hemicellulose, and lignin —are shown.Alian. M, Balan. V. (CC0 1.0).

This plant biomass is renewable, abundant, and inexpensive, making it ideal for the cultivation of saprophytic mushrooms such as Pleurotus, Lentinula, and Ganoderma. These fungi secrete extracellular enzymes to break down the biomass into usable nutrients. Starch hydrolyzed by enzymes such as alpha and gluco-amylase to produce glucose; Cellulose (35–50%) Hydrolysis by cellulase enzymes provides glucose, while hemicellulose (20–35%) hydrolyzed by hemicellulase enzymes releases mixed sugars such as xylose, arabinose, and mannose. Lignin (10–25%) requires oxidative enzymes such as laccases and peroxidases for degradation. Typical substrates include rice and wheat straw, maize stalks, hardwood sawdust, cottonseed hulls, sugarcane bagasse, sorghum stubble, coconut coir, coffee husks, and banana stem waste. These materials are usually shredded, moistened, and pasteurized or sterilized before being inoculated with fungal spawn to initiate colonization and fruiting. Fungi produce a variety of enzymes to break down lignocellulosic biomass and grains, giving them access to carbon and nutrients. The most crucial enzyme classes are listed in Table 15.3. These enzymes work synergistically to convert complex plant polymers into absorbable nutrients for fungal colonization and fruiting.

Table 15.3 Fungi and their specific properties secrete enzymes.

| Enzyme | Types | Properties |

|---|---|---|

| Cellulase | Endoglucanase (Cel5A), Exoglucanase [Cel7A, CBHI and Cel6A (CBHII)], β-glucosidase | Endo and Exoglucanase hydrolyze cellulose from the ends, releasing cellobiose. |

| β-Glucosidase hydrolyze cellobiose and other cello-oligosaccharides into glucose. | ||

| Hemicellulase | Xylanase, Mannanase, Arabinofuranosidases | Xylanases hydrolyze xylan, a major component of hemicellulose. |

| Mannanases hydrolyze mannans and glucomannans. | ||

| Arabinofuranosidases hydrolyze arabinose residues from arabinoxylan and arabinan. | ||

| Lignin-degrading enzymes | Laccases, Lignin peroxidase (LiP), Manganese peroxidase (MnP) | Laccases oxidize phenolic compounds and aromatic amines. |

| LiP oxidizes non-phenolic lignin structures. | ||

| MnP oxidizes Mn (II) to Mn (III), which then acts as a diffusible oxidant for lignin. | ||

| Amylase | a-amylase (AM), | AM is an endo-acting enzyme that cleaves internal α-1,4 glycosidic bonds. |

| b-amylase (BM), | BM is an exo-acting enzyme that releases maltose from the non-reducing end. | |

| g-amylase (GM, glucoamylase) | GM cleaves both α-1,4 and α-1,6 glycosidic bonds from the non-reducing end, producing glucose. |

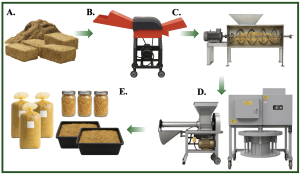

Efficient mushroom cultivation begins with the careful preparation of substrates that provide structural support and essential nutrients for fungal growth. Substrate preparation involves a series of steps — from mechanical processing to nutrient enrichment — that are tailored to the specific physiological needs of the cultivated fungal species. While manual techniques are sufficient for small farms, commercial production benefits greatly from mechanized systems that ensure consistency, efficiency, and contamination control.

Size Reduction of Raw Biomass

Lignocellulosic materials such as straw bales, corn stover, spent grains, cotton stalks, and wood chips must first be comminuted to improve their usability as mushroom substrate. Mechanical equipment such as hammer mills, choppers, and shredders is used to reduce the raw biomass into smaller particles, usually about 1 to 2 inches long. This shredding improves the uniformity of the substrate, facilitates moisture and heat penetration during sterilization or composting, and increases the surface area for enzymatic degradation. While volume reduction is essential, excessive shredding should be avoided as it can lead to compaction, poor aeration, and inhibited mycelial growth. Of course, fibrous texture is the optimum balance for most mushroom species.

Blending & Amending Ingredients

Once the raw biomass is the right size, it is mixed with various additives to obtain a nutritionally balanced and physically suitable substrate. Carbon-rich bare substrates — such as straw or sawdust — are supplemented with nitrogen-rich components such as wheat bran, soya meal, or poultry manure. Additional additives such as gypsum (CaSO₄-2H₂O) or lime (CaCO₃) can be added to buffer the pH value and improve the texture. The humidity is adjusted to 60–70%, which is optimal for fungal colonization. For species such as Agaricus bisporus (mushroom), the mixed substrate is subjected to composting — a microbiologically controlled, aerobic preconditioning process using static heaps, rotating windrows, or composters in vessels. This step breaks down complex polymers such as lignin and cellulose, enriches microbial communities, and stabilizes the substrate, improving its bioavailability and selectivity for fungal colonization. Proper mixing and composting ensure even nutrient distribution and physical consistency, laying the foundation for vigorous mycelial growth and successful fruiting.

Packaging Substrate

After mixing, the prepared substrate is portioned into standardized units such as autoclavable polypropylene bags, glass or plastic bottles, or cultivation plastic or wooden trays, depending on the type of mushroom and production system (Figure 15.10). These containers are designed to withstand sterilization or pasteurization while supporting mycelial colonization.

Figure 15.10 Substrate preparation steps. Here, A: Substrate storage, B: Substrate milling, C: Substrate mixing in the Ribbon mixer machine, D: Bagging and bottling machine, E: Packed substrate in bags, bottles, and trays. Alian. M, Balan. V. (CC0 1.0).

Uniform packaging ensures consistent substrate volume and density, which is critical for effective heat transfer, aeration, and microbial control during subsequent sterilization or pasteurization steps. Both manual and automated packaging systems can be used to fill and seal containers with precise amounts of substrate. Sealing—usually with cotton plugs, microporous adhesive tape, or heat-sealed filters—prevents contamination and at the same time enables gas exchange. Properly packaged units facilitate rationalized handling during inoculation, incubation, and fruiting. Efficient and consistent substrate packaging not only improves hygiene and workflow but also supports scalability and reproducibility in commercial mushroom production. Using biodegradable plastic materials will help reduce environmental pollution.

Sterilization and Pasteurization Process

These procedures are critical processes in mushroom cultivation that serve to eliminate or suppress competing microorganisms in the substrate before fungal inoculation. The choice between sterilization and pasteurization depends on the type of mushroom species, the scale of production, and the substrate used. Proper sterilization not only increases the efficiency of fungal colonization but also reduces crop losses due to microbial competition. Table 15.4 lists the advantages and limitations of the various sterilization methods.

Table 15.4 Different sterilization and Pasteurization methods.

| Disinfection method | Advantage | Disadvantage | Reference |

|---|---|---|---|

| Steam Sterilization | Most reliable sterility | High energy demand | [24] |

| Kills all vegetative microbes. | Requires costly equipment | ||

| Prevents competitor molds | |||

| Pasteurization | More energy efficient Moderate equipment costs Adequate pathogen reduction | Doesn't fully sterilize | [24] |

| Risk of some residual contamination | |||

| Hydrated lime Bath | Provides high pH inhibition No need for steam | Very lengthy process | [24] |

| Well-studied for Agaricus | Excess lime must be rinsed off | ||

| Can't sterilize, only pasteurize |

Steam Sterilization (Autoclaving)

Sterilization involves the complete killing of all living organisms, including bacterial spores, by exposure to saturated steam at high temperatures. It is usually performed in an autoclave or steam chamber at 121°C (250°F) under a pressure of 15 psi for 30–90 minutes, depending on the volume and density of the substrate. This method is essential for species such as Shiitake and Ganoderma, which grow on nutrient-rich, finely milled substrates that are more susceptible to contamination. Sterilization is ideal for small or high-value mushroom plants where contamination control is critical.

Pasteurization

This process aims to reduce the population of harmful microbes while preserving some beneficial heat-tolerant organisms. It is commonly used for the cultivation of species such as Pleurotus (oyster mushrooms) on low-cost agricultural residues. Pasteurization is usually carried out by treating the substrate with hot water (60–80°C) or steam (atmospheric pressure) or by impregnation with compressed air for 1–4 days, depending on the method used. Techniques include immersion in hot water, steam pasteurization in insulated tunnels, or barrel systems.

Hot Water Treatment

In hot water pasteurization, mushroom substrates are immersed in tanks or barrels of 60–80°C hot water for a specific period to reduce the microbial load. Compared to steam sterilization or autoclaving, this method uses less energy and does not require high-pressure equipment, making it more accessible for small producers. However, larger volumes of water are generally required per unit of substrate, and not all contaminants may be consistently removed. Nevertheless, hot water pasteurization remains a practical and cost-effective disinfection method for growers with limited resources.

Chemical method

In this method, substrates are treated with antimicrobial agents to suppress or eliminate competing microorganisms. Commonly used chemicals include hydrogen peroxide, formaldehyde, chlorine-based disinfectants, and calcium hydroxide (hydrated lime). These agents work by destroying the cell walls of microorganisms, denaturing proteins, or changing the pH value to create unfavorable conditions for contaminants. Hydrated lime, for example, increases the pH of the substrate and selectively inhibits bacterial and fungal competitors without completely sterilizing them. Small growers often use chemical treatments as they require little equipment. However, care must be taken to avoid toxic residues and to ensure safe handling during preparation and spawning [23].

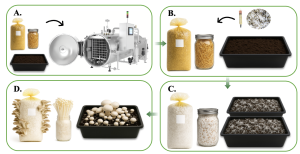

15.8 Substrate Inoculation and Incubation

Substrate inoculation involves the introduction of fungal spawn — either in solid form (e.g., grain or sawdust-based) or in liquid form — into prepared, sterilized, or pasteurized substrates to initiate mycelial growth. Standard methods include thorough mixing, layering on the surface, spawn sacs, or the insertion of dowels for cultivation on logs. After inoculation, the substrate is incubated in a dark, clean environment at 22–28°C with limited air supply to maintain an elevated CO₂ content, which favors vegetative mycelial spread. Strict hygiene, clean room practices and monitoring for contamination are essential at this stage to ensure healthy colonization and prevent competing microbial growth.

Inoculation Methods

Inoculation of fungal substrate can be carried out using a variety of techniques tailored to the growing system and fungal species (Figure 15.11). Mixing involves mixing the mushroom spawn evenly into the loose substrate, creating multiple mycelial growth points for rapid colonization.

Figure 15.11 Mushroom cultivation steps. Here, A: Sterilizing the packed substrate through autocalving, B: Inoculation with liquid or solid spawn, C: Incubation at a specific temperature for complete colonization, D: Mushroom growing. Alian. M, Balan. V. (CC0 1.0).

Layering involves alternating layers of mushroom spawn and substrate, which is often used when cultivating in trays or beds to ensure even distribution of mycelia. Spawn bags are pre-packaged substrate units that are inoculated with spawn and sealed for controlled incubation, reducing the risk of contamination and improving handling. The insertion of plugs is often used in the cultivation of tree trunks. Wooden dowels colonized with mycelium are inserted into drilled holes, resulting in local inoculation that spreads over the boot over time. Each method offers advantages depending on the scope, substrate type, and desired production result.

Incubation Conditions

During incubation, maintaining optimal environmental conditions is crucial for the successful colonization of the substrate by mycelium. Temperatures are usually between 22 and 28°C, depending on the fungal species, to promote vigorous fungal growth. Darkness or low light is preferred, as light can inhibit the spread of the mycelium at this stage. In addition, it is essential to monitor and control CO₂ levels, as increased carbon dioxide produced by the growing mycelium can affect growth patterns and trigger premature fruiting. Adequate aeration or CO₂ scrubbing will ensure the correct balance and promote healthy, even colonization before fruiting begins.

Contamination Control

Effective contamination control is essential during mushroom cultivation to prevent unwanted microbes from competing with or harming the fungal mycelium. Clean room practices—such as working in laminar flow hoods, sterilizing tools and surfaces with disinfectants, and wearing protective clothing—help maintain a sterile environment during inoculation and incubation. In some cases, the use of approved antimicrobials or fungicides may be necessary to suppress persistent contaminants. Regular monitoring and quick removal of contaminated substrates further

reduce the risk of contamination spreading, ensuring healthy fungal growth and high yields [28, 29].

15.9 Fruiting Body Induction, Harvesting, and Packaging

Fruiting body induction is the process by which the adjustment of environmental factors such as temperature, humidity, light, and fresh air exchange triggers the development of the fungus from the fully colonized mycelium. Optimal conditions vary depending on the species, but generally include lowering CO₂ levels, maintaining high humidity (80–95%), and providing suitable light cycles. Once the mushrooms are ripe, they are carefully harvested by hand so as not to damage the substrate or remaining mycelium to ensure subsequent sprouting. Timely harvesting preserves the quality, flavor, and shelf life of the mushrooms.

Induction triggering

The formation of fruiting bodies in fungi is stimulated by specific environmental stimuli that signal to the mycelium the transition from vegetative growth to reproduction. The most essential triggers include a drop in temperature (cold shock), increased fresh air or reduced CO₂ levels, increased humidity (typically 80–95%), and exposure to light of a certain intensity and photoperiod. Species, such as the king oyster, scratch the surface of the colonized substrate and are impacted with fresh water. These factors vary from species to species, but together they create optimal conditions for the formation of primordia and the development of fruiting bodies and initiate the visible growth phase of the fungus.

Harvesting Techniques

Mushrooms are usually harvested when the caps have reached the desired opening stage, which varies depending on the species and market preference — either just before the cap fully expands or just after. The timing also depends on the weight of the fruit and quality standards to ensure optimum freshness and shelf life. Harvesting is carried out by gently cutting or twisting at the base of the stalk to avoid damaging the underlying substrate, preserving the mycelium for the subsequent flowering periods, and ensuring the overall yield [30, 31].

15. 10 Cleaning the grwoth chmaber

Cleaning the growth chamber after each mushroom cultivation cycle is a critical step in reducing contamination risks. Most contaminating organisms, including molds, bacteria, and competing fungi, thrive in moist environments. Many of these microbes produce spores that can disperse easily and persist in the chamber, contaminating subsequent batches of mushroom substrates and reducing yield. Once a mushroom growth cycle is complete, all spent substrate bags must be promptly removed from the chamber. This is followed by thorough cleaning of the racks, floors, and walls, typically using high-pressure washing to eliminate visible debris and residues. After the physical cleaning stage, a chemical or gaseous disinfection process is applied to reduce microbial loads further. Common practices include the use of ozone fumigation or aerosolized (atomized) hydrogen peroxide, both of which are highly effective in penetrating hard-to-reach areas such as corners, ventilation ducts, and crevices in equipment. These disinfectants neutralize microbial spores, ensuring a hygienic environment for the next cycle. Following treatment, the chamber must be appropriately vented to remove residual gases and ensure worker safety. Once the chamber environment is clean, dry, and free of disinfectant residues, fresh substrate bags can be loaded, and a new cultivation cycle can begin. Consistently implementing this cleaning and disinfection protocol not only reduces contamination risks but also promotes higher yields, better mushroom quality, and more sustainable long-term production.

15.11 Post-harvest processing and quality evaluation

Post-harvest processing of mushrooms includes cleaning, sorting, grading, and packaging to ensure the safety of the product. Cleaning the mushrooms removes dirt and debris without damaging the fruiting bodies. Mushrooms are sorted and graded based on their size, shape, and quality, and adequately packaged to protect from physical damage, moisture loss, and microbial contamination during storage, handling, and transportation. Quality assessment is a key step in mushroom farms that evaluates various factors such as firmness, color, moisture content, aroma, and signs of spoilage. Regular inspections should be done to maintain freshness, extend shelf life, and ensure that the mushrooms meet the legal regulations and market requirements, and deliver to the customers with high quality [30]

Quality Parameters

The quality of mushrooms is assessed based on various key parameters. Physical characteristics such as size, shape, and firmness are decisive for consumer appeal and market classification. The absence of contaminants such as mold, bacteria, or insect infestation is crucial for safety and shelf life. The microbial load is monitored to meet HACCP (Hazard Analysis and Critical Control Points) standards and ensure that the mushrooms are safe and hygienic to eat. Biochemical tests assess the content of bioactive substances, including antioxidants and polysaccharides, which reflect the nutritional and medicinal value. Moisture content is carefully monitored and controlled to prevent spoilage.

Processing and packaging

Fresh mushrooms are highly sensitive and must be carefully packaged and transported to preserve quality. Breathable materials such as perforated plastic trays or cardboard boxes are recommended for packaging to allow air circulation and prevent moisture trapping that can lead to spoilage. Temperature control is crucial during transport; the ideal temperature is between 1–4°C and high relative humidity (85–95%) to prevent dehydration. Rapid cooling after harvesting and maintaining the cold condition during transport will preserve freshness, texture, and nutritional value until the mushrooms reach the consumer or processing plants. One way to inhibit microbial spoilage and reduce moisture loss is by applying edible coatings or natural antimicrobial agents, such as chitosan, oils, or organic acids. These treatments create a protective barrier and extend the mushroom shelf life without reducing food safety or quality. Some advanced technologies, such as gamma irradiation, are used to reduce microbial load and increase mushroom shelf life.

Labeling, Storage, and Shelf-Life Testing

Proper labelling of mushroom packages is an important step that helps customers make informed decisions. A good label provides information, such as the species name, harvest date, origin, storage instructions, and expiry date. Mushrooms should be stored at low temperatures (around 1–4°C) and controlled humidity to slow down spoilage and preserve quality. Shelf-life testing monitors physical, chemical, and microbiological changes over time under specific storage conditions to determine the safe shelf life of the product and help to optimize packaging and storage protocols to reduce waste and deliver mushrooms to the consumer in the best possible condition.

15.12 Prospects and Innovations in Fungal Biotechnology

Fungal biotechnology provides sustainable solutions in various sectors, including agriculture, medicine, and industry, by offering novel biomaterials, extracting bioactive substances for fungal pharmaceuticals, producing biofuels, and developing enzymes. Recent advances in genetic engineering and synthetic biology have improved fungi with higher yields, higher stress tolerance, and the ability to produce new metabolites. In addition, the help of modern technologies such as the Internet of Things (IoT) and automation makes mushroom cultivation more efficient. Fungal biotechnology is expected to contribute to addressing global challenges in the areas of health, environmental sustainability, and resource management.

Mycelium-based leather, packaging, and meat analog

Mycelium, the root-like network of fungal filaments (hyphae), has been utilized as a sustainable material with diverse applications across various industries. Ganoderma is one of the most common fungi that has been widely used due to its firm texture and specific properties, making it an ideal option. Mycelium-based materials, such as leather, packaging, and construction materials, offer multiple advantages compared to conventional materials. They are versatile, biodegradable, and have a low environmental footprint, which makes them a sustainable and promising alternative to fossil fuel-based materials. In the fashion industry, mycelium-based leather has been used as an alternative to animal leather. It is sustainable and environmentally friendly compared with animal leather, which is made by toxic tanning agents and consumes a high amount of water during the production process. Mycelium leather grows in just a few days, requires minimal water and energy, and does not involve animal cruelty. It is naturally biodegradable, durable, and can be processed to mimic the texture, elasticity, and appearance of animal and artificial leather.

Mycelium can be used as a packaging material and grown in customized molds to form lightweight materials in various shapes and sizes. They can be replaced with polystyrene or plastic foams. Mycelium-based packaging materials are eco-friendly and decompose naturally within a week, while petroleum-based plastics last for centuries and come with a considerable carbon footprint. This makes it useful for various applications, including electronics, fragile goods, and shipping products, which aligns with circular economy principles and reduces landfill waste. Pure mycelium is consumed as a food product in different ways, such as veggie sausage, bacon, and burgers. Due to its fibrous structure, it can mimic the texture of meat and provide a high protein content and essential nutrients to the customers. Mycelium proteins can be produced with minimal processing and naturally absorb flavors and spices thanks to their unique flavor. (Figure 15.12A).

Value-added products of mushrooms

Value creation in mushroom production plays a crucial role in improving profitability and sustainability. By transforming perishable fresh mushrooms into a wide range of shelf-stable, high-value products, such as dried mushrooms, mushroom powders, extracts, teas, capsules, and ready-to-eat meals, growers can significantly extend shelf life and reducepost-harvestt losses. These products fulfill various consumer demands, including health-conscious markets, culinary applications, and nutraceutical sectors. In addition to reducing waste, value-added processing diversifies income streams, opens access to national and international markets, and enables small and large growers to serve niche segments. It also increases the resilience of mushroom farms by enabling year-round sales, even when fresh production is seasonal.

Figure 15.12 Produced value-added products. Here, A: Mycelium applications in different industries such as food, fashion, pharmaceutical, and packaging. B: Mushroom products include freeze-dried powder, pickling, extract, snacks, and canning. Alian. M, Balan. V. (CC0 1.0).

Ultimately, value creation increases the versatility of products and contributes to the economic viability and competitiveness of mushroom cultivation on the global market (Figure 15.12B).

Freeze drying and grinding to powder

To extend the shelf life of mushrooms, various drying methods are used to remove the moisture, which inhibits the microbial growth and enzymatic activity that cause spoilage. These techniques include sun drying, hot air drying, oven drying, and freeze drying, each of which has its advantages and limitations. Sun drying is a traditional and cost-effective method, and highly dependent on weather conditions, and carries a higher risk of contamination by dust and insects. In contrast, hot air drying and oven drying at controlled temperatures (usually between 40–60°C) efficiently remove moisture while preserving the flavor and nutritional content of the mushrooms. Freeze-drying is the most advanced and effective method. It involves freezing the mushrooms and then reducing the ambient pressure so that the frozen water sublimates directly from solid to gas. This process preserves the texture, color, and nutritional value better than other methods. Once dried, mushrooms are lightweight, can be easily ground into a fine powder using tools such as a Wiley grinder, and are convenient to store or transport. They are also easy to rehydrate and incorporate into culinary applications. These characteristics make dried mushrooms an ideal choice for long-term storage, emergency food supply, and commercial distribution, especially in the nutraceutical and functional food industries.

Mushroom extracts

Depending on the chemical nature and polarity of the target molecules, different solvents are used to extract bioactive compounds from fungi. Water is generally used for the extraction of polysaccharides, especially β-glucans, which are valued for their water solubility and strong immunomodulatory effect. For less polar compounds, solvents such as ethanol, methanol, and acetone are more effective. These are used to isolate phenolic compounds, terpenoids, and sterols, which are known for their antioxidant, anti-inflammatory, and antimicrobial effects. The solvent-extracted compounds are used in pharmaceuticals, dietary supplements, capsules, functional foods, and cosmetic products. Mushroom extraction is a promising product, and by using a particular solvent, specific bioactive groups can be extracted.

Mushroom pickling

Pickling is another preservation method of mushrooms that enhances the mushroom flavor. Typically, a mixture of vinegar, oil, salt, and spices is used to make pickled mushrooms. It typically begins with washing and blanching fresh mushrooms in hot water for a few minutes to soften the texture and reduce microbial load. They are then flavored with a seasoning powder, typically consisting of mustard seeds, chili powder, turmeric, garlic, vinegar, and cooking oil. The mixture is briefly boiled, cooled, and then packed into sterilized jars, allowing it to be stored for a long time. Pickled mushrooms retain their nutritional value, texture, and taste, and their growing popularity reflects increasing demand in local and international markets.

Canning

Canning is an effective method for the long-term preservation of mushrooms. In this process, the prepared mushrooms are placed in jars, sealed, and subjected to heat treatment – usually a hot water bath or pressure canning. This step is important to eliminate any remaining microorganisms, ensuring both safety and a longer shelf life. The jars must be sealed and stored in a cool, dark environment to preserve their quality, and can be reused for a long time. This technique offers small producers and food entrepreneurs a reliable way to extend the shelf life of their products while increasing the value of fresh mushrooms.